Simulation | 製作安全的包裝,更好地保護你的產品

日期:2024-02-07 16:48:42 發布者: 瀏覽次數:次

Lunar New Year is coming, and many companies are preparing unique packaging designs for customers. However, how do make sure the package is safe enough to ship around the world? To do this, the package will need to go through testing: Drop Test.

Drop test is one of the essential tests for many different industries. To ensure the success of drop test, it is very common to make a sample and test it physically. For conventional packaging or simple design, it might be rather safe and mostly able to pass the test in one go. However, as green /customized packaging starts to be a new trend and requirement for packaging, it has become more difficult to design a packaging with the lowest cost. As a result, companies might need a few more iterations to achieve the desired goal.

When making samples and conducting trial-and-error start to get expensive and time consuming, it is better to first simulate the design rather than just make a sample and test it physically. There are several ways to help design packaging using simulation tools. Let’s look at the following case:

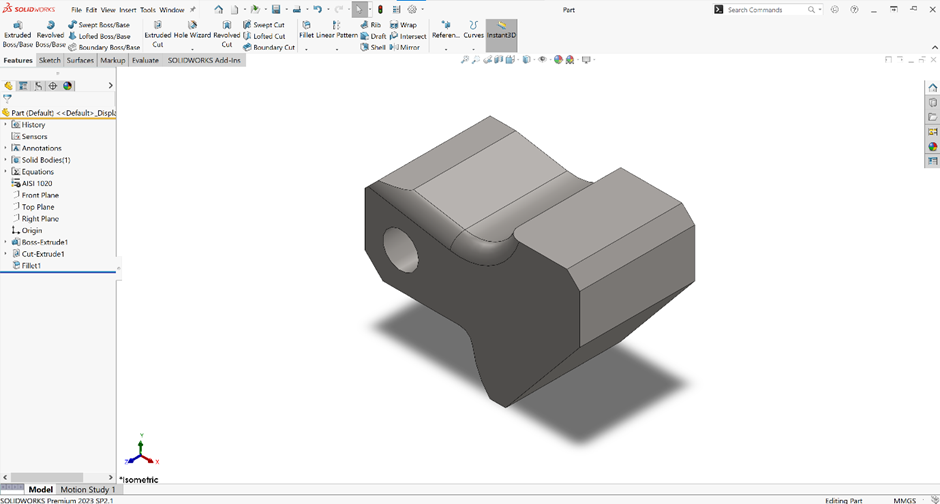

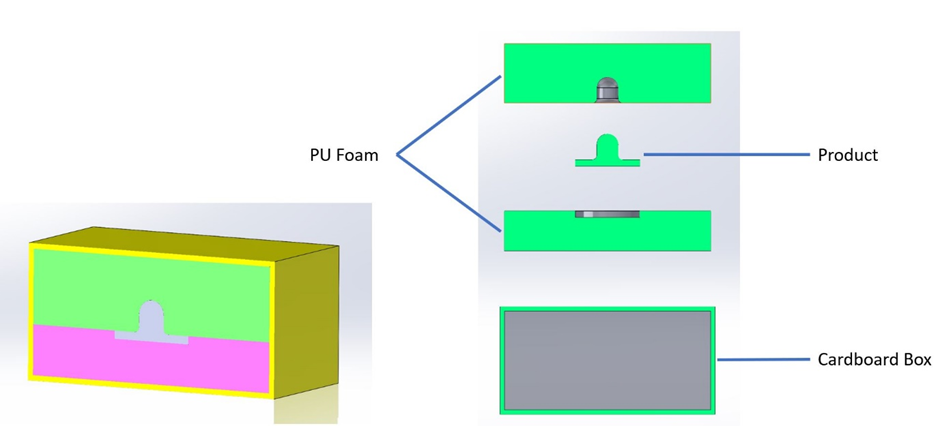

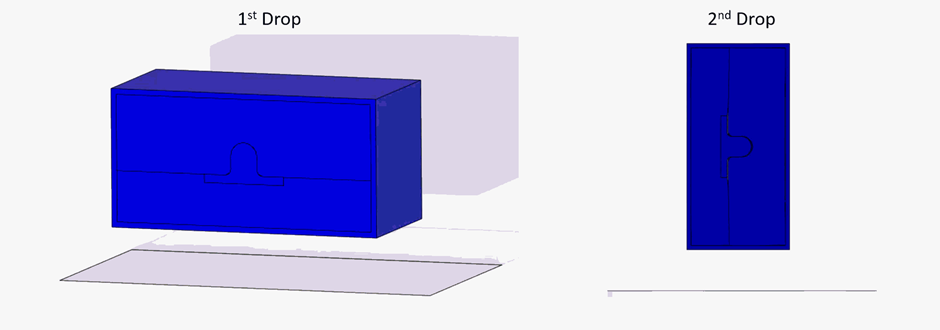

Here we have a very simple package, we will use this model to demonstrate drop test simulation using different methods:

The following is the shedinned material for each part:

Cardboard Box: Corrugated Cardboard

Packaging Material: Soft PU Foam

Product: Alloy Steel

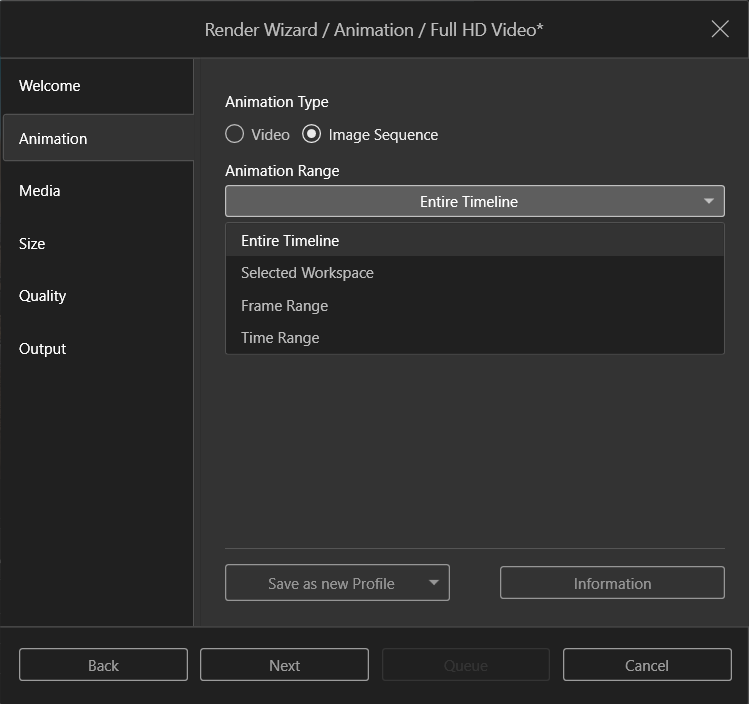

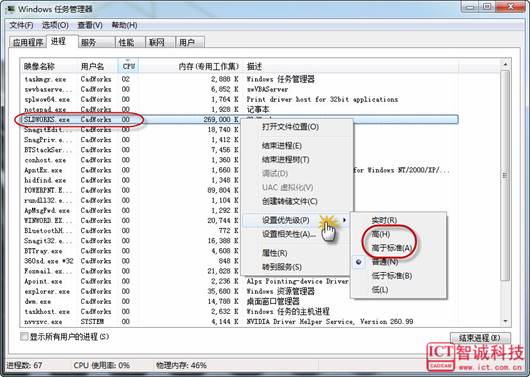

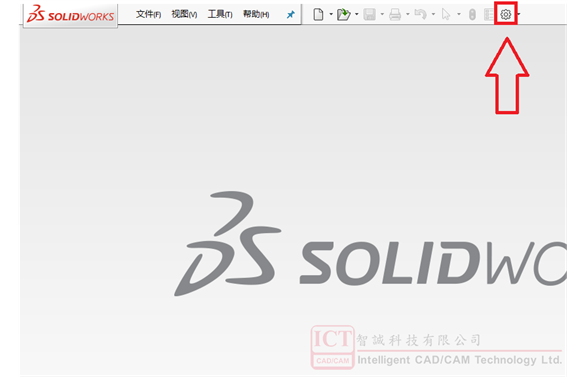

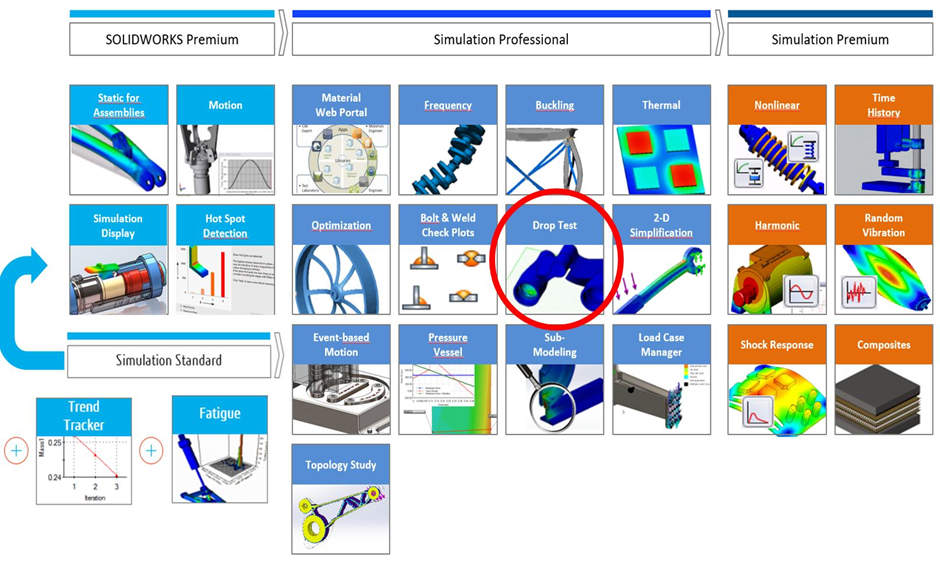

One of the methods is to use Soliworks Simulation Professional. By using it’s Drop Test Simulation, you can conduct drop test within Solidworks while designing the package using Solidworks.

Solidworks Simulation Professional’s Drop Test is able to provide preliminary studies on the position and value of stress concentration easily.

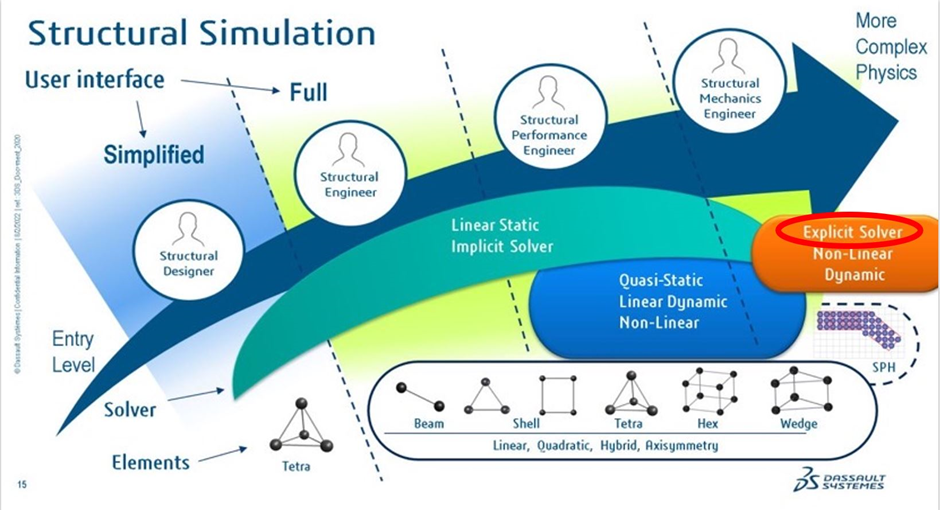

But what if we needed more (e.g. including buffering materials, sequential drops, etc.) for the packaging evaluation? For this, we will have to use 3DExperience Platform’s Structural Mechanics Engineer to conduct an Explicit Dynamic Preloaded Study.

By using 3DExperience Platform’s Structural Mechanics Engineer, you can conduct comprehensive and accurate drop test analysis with the help of World-Class Solver Abaqus.

To conclude, there are many different ways to conduct drop test simulation. If your product is relatively simple and preliminary result is enough, Solidworks Simulation Professional will be suitable for you. However, if you require in-depth and complex drop analysis such as sequential drops, then 3DExperience Platform’s Structural Mechanics Engineer will be a better choice.