Simulation | 測試燈籠的熱力流動

日期:2023-09-28 17:02:56 發布者: 瀏覽次數:次

Mid-Autumn Festival its coming and everyone is readying their festival lanterns to show-off. There are tons of different lanterns in the market and most of them are using LED lights nowadays as it is much safer to use.

Let’s say you are a designer of the lanterns and you want to go back to the roots and try to replace LED light bulb with candle inside your lanterns. However, candle produces real flame and you are not sure whether it is safe to directly replace LED light bulb. You can, of course, build a prototype and test it out yourself.

However, this usually takes a lot of resources (time, money, etc.) and may even delay your whole production cycle if several prototypes are required. So, what can you do to make sure the design is safe AND be able to follow the production schedule? This is where Solidworks Flow Simulation comes to help.

Solidworks Flow Simulation is a Computational Fluid Dynamic software that can help the user to conduct “What-if Scenarios” on different situations required to calculate fluid dynamics. Let’s use the above example to see what can it do:

Here we have two scenarios:

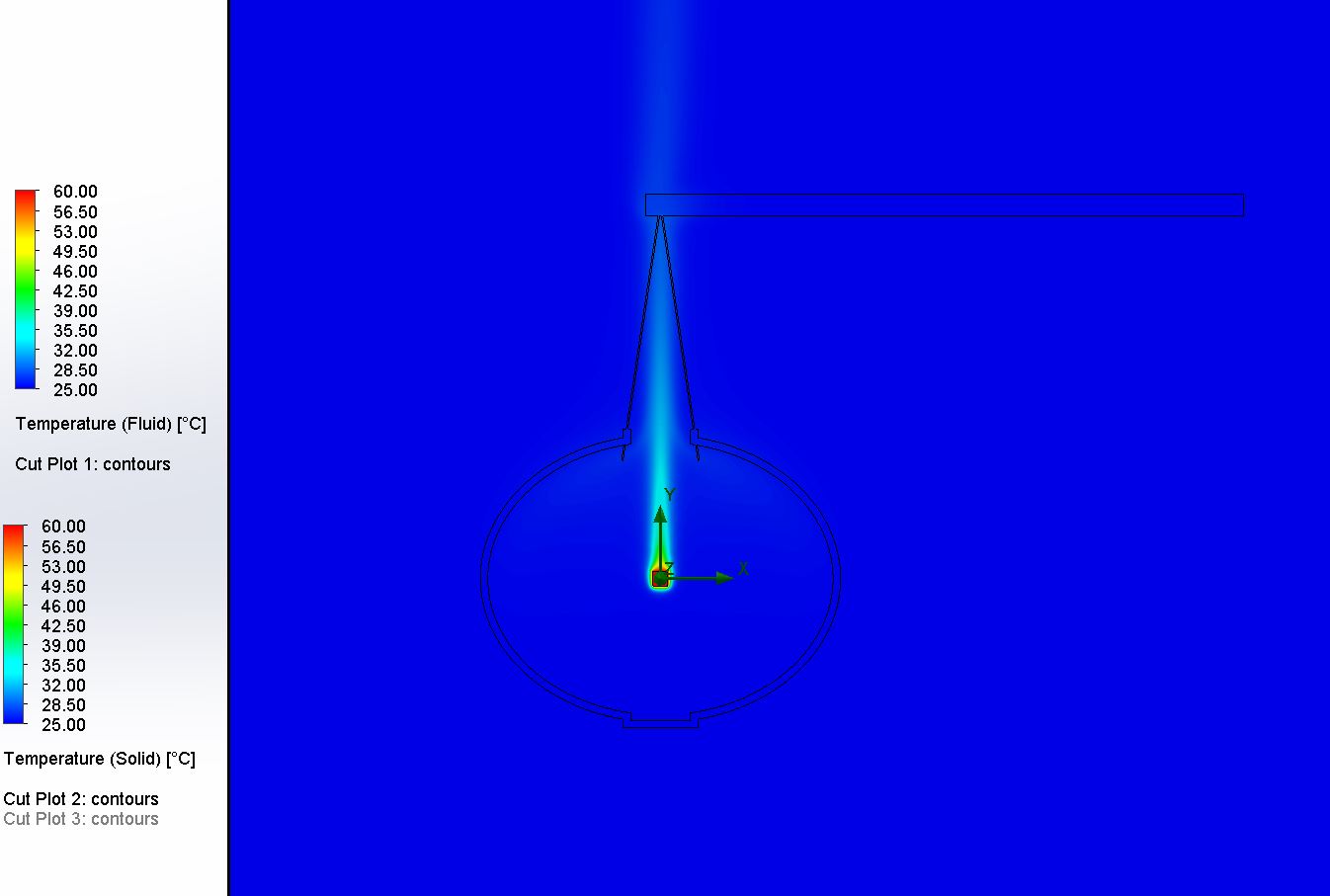

- Lantern with LED light bulb (Assume light bulb temperature: 60°C)

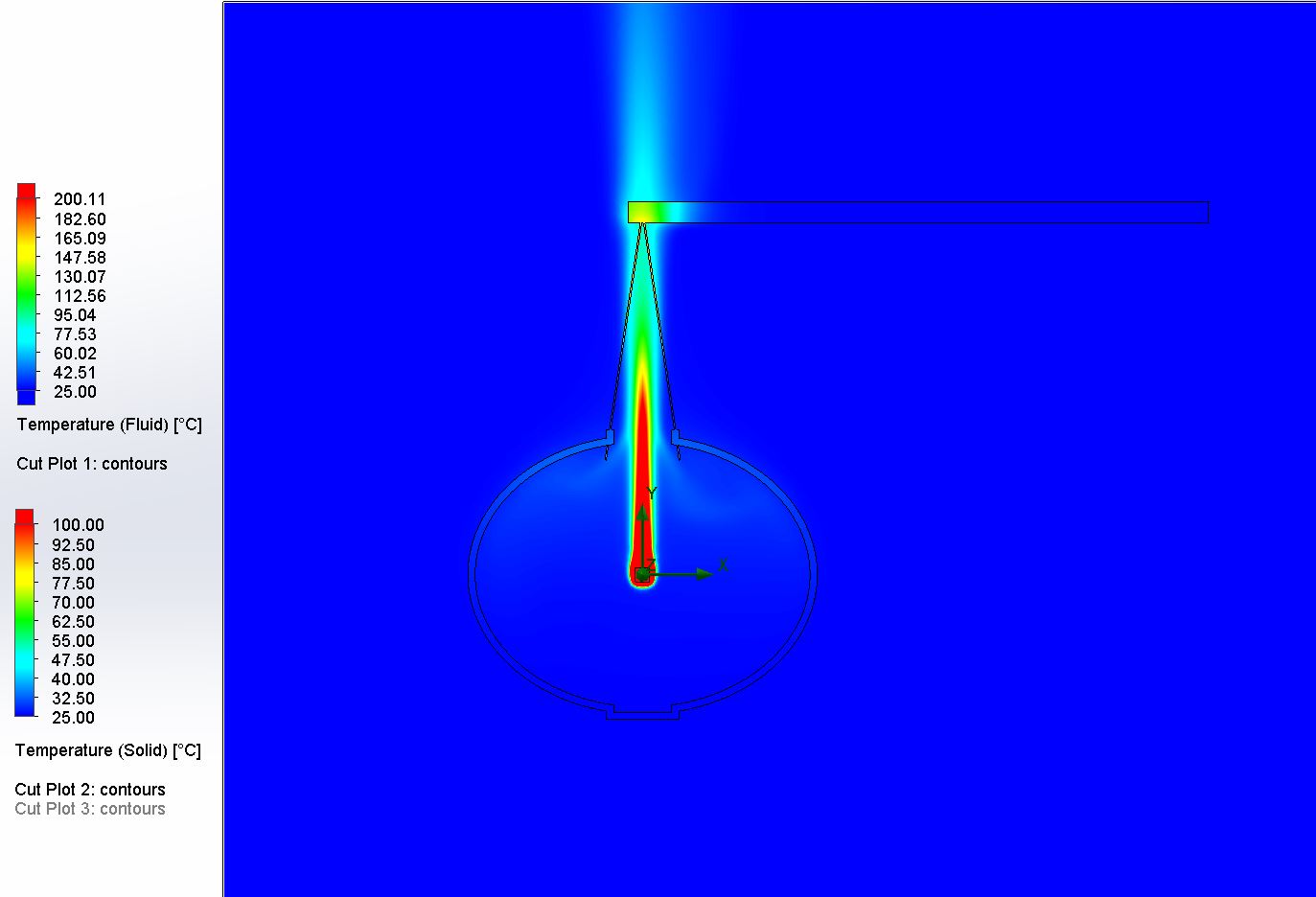

- Lantern with candle (Assume candle flame temperature: 1000°C)

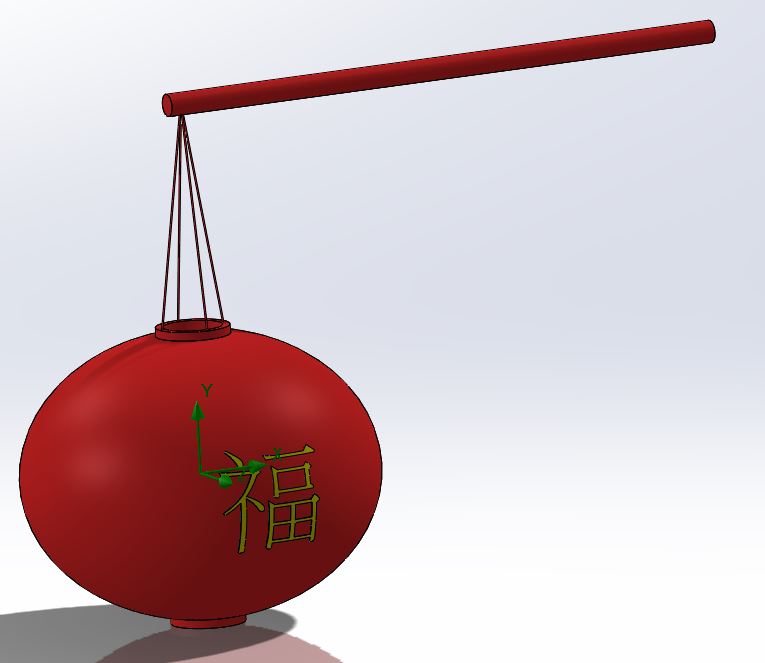

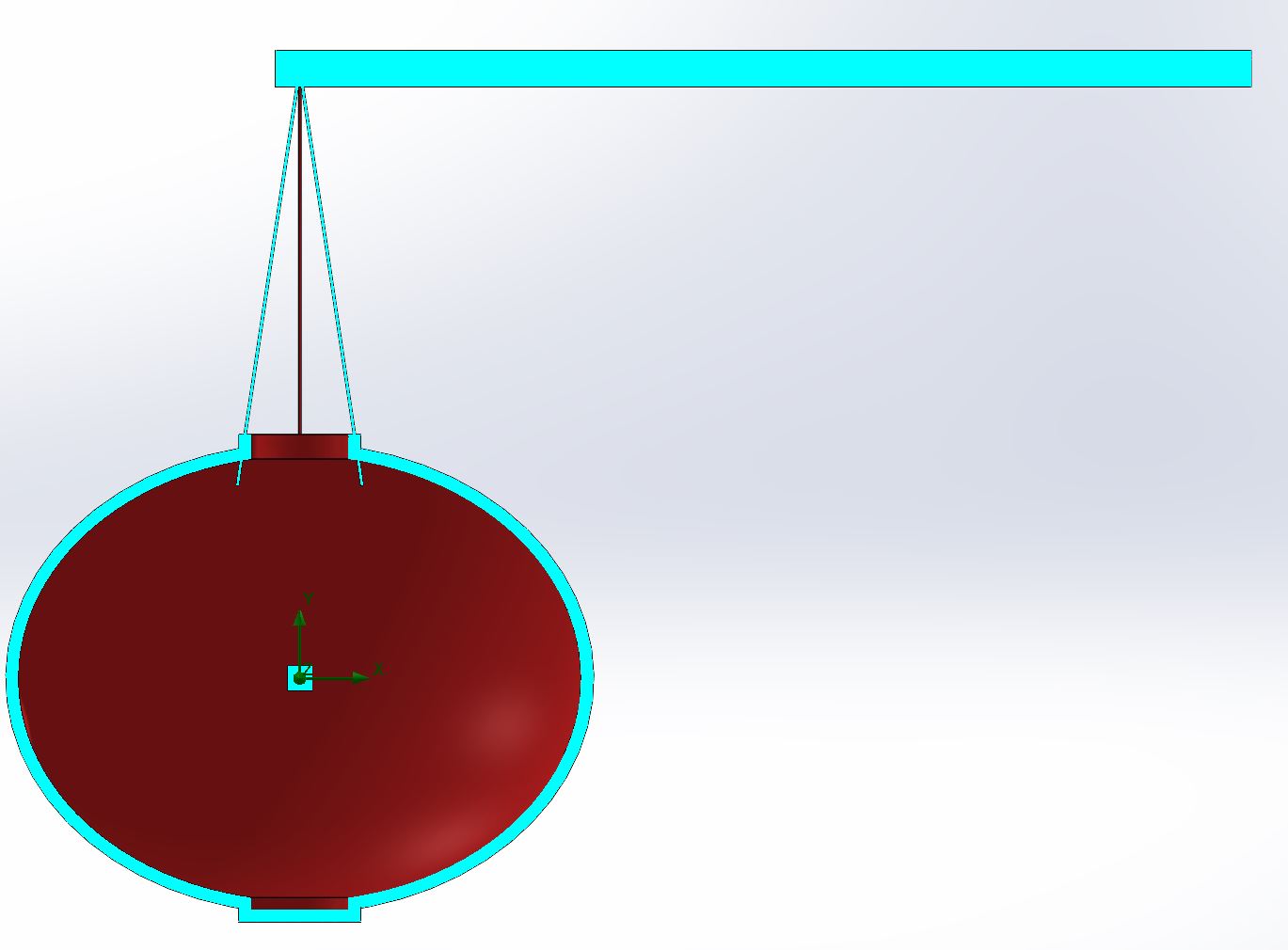

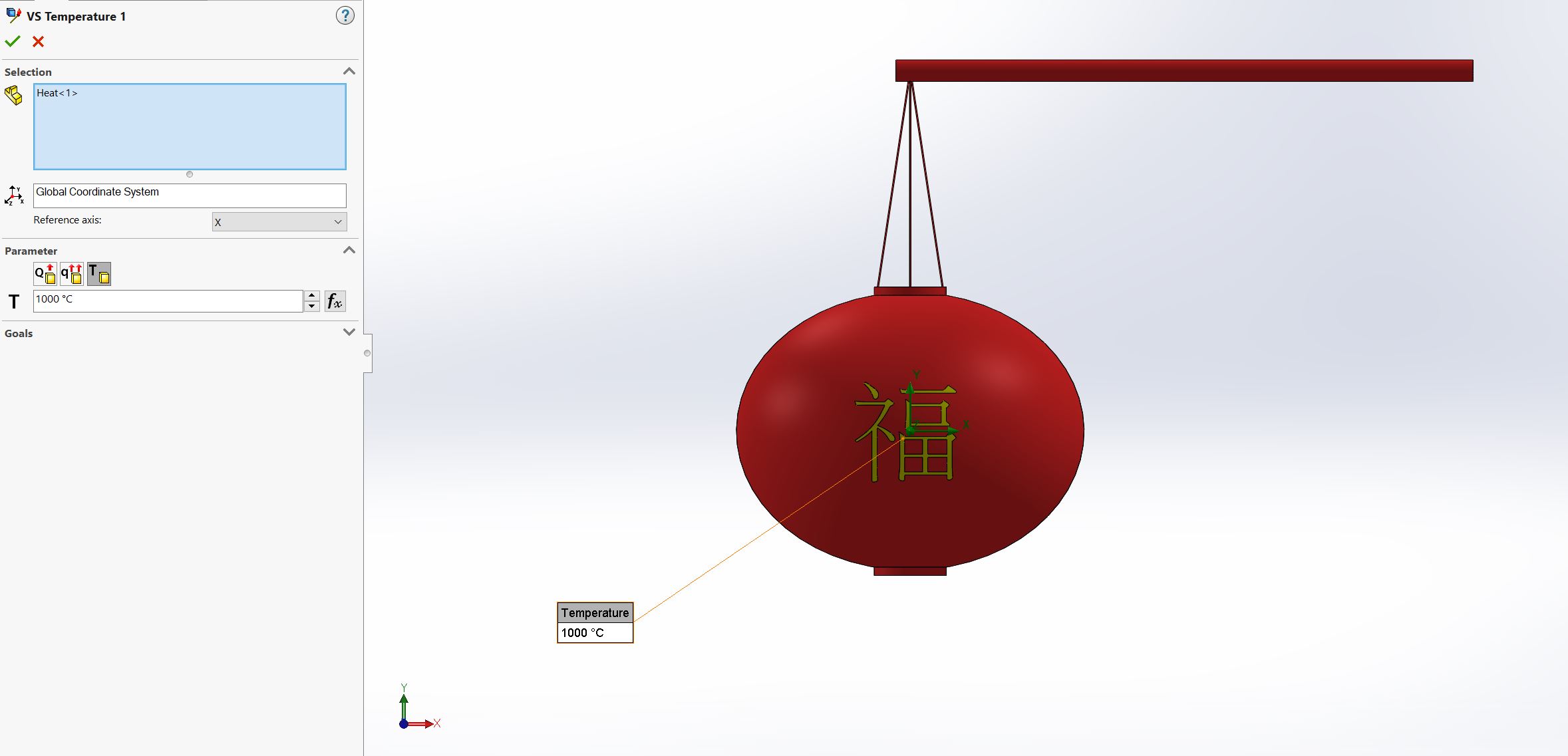

First, we need to build a simplified model for the simulation. A 10x10x10 mm cube was placed in the middle of the lantern to represent the heat source (i.e. LED light bulb / candle flame).

Then, we will need to set up the boundary conditions and initial conditions, which will represent the situation of said simulation.

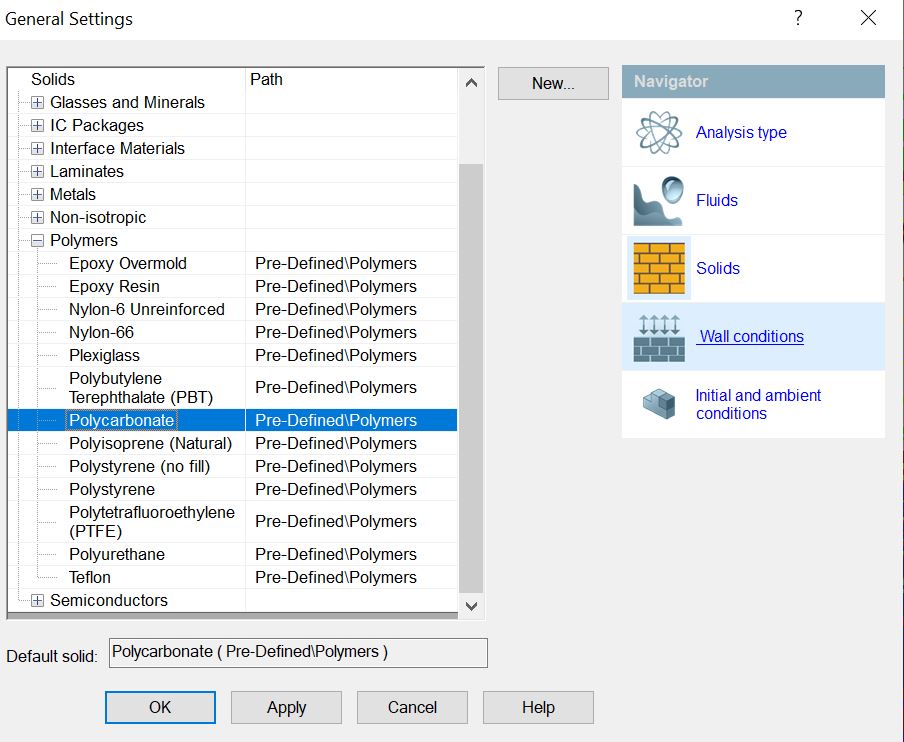

We will assume the whole lantern is made of Polycarbonate (PC) and the ambient temperature is 25°C.

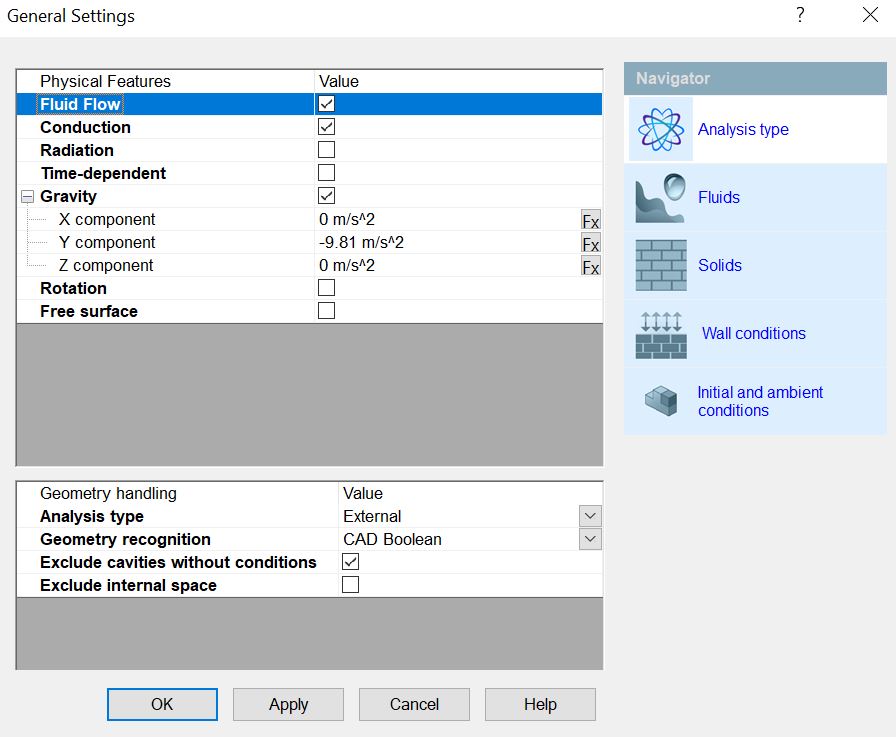

Realistically, we have gravity around us, so we will set the gravity as 9.81 m/s^2.

For the heat source, we can set Heat Generation Rate (W) or Temperature (°C), we will set the block using Temperature.

After running the simulations, we now have the results. Let’s see how different will the air temperature be:

As we can see, using LED light bulb will have no issue as the temperature is just 60°C.

However, when replacing LED with candle, the temperature raised a lot and may led to the plastic parts melting.

Other than temperature plots, we can also generate flow trajectories to see how the fluid flow behaves.

Gif here

By using Solidworks Flow Simulation, we can easily evaluate different design scenarios and choose the most promising to verify with prototype. Thus, saving your design resources and making sure your products can meet the production date.

Written by Mo