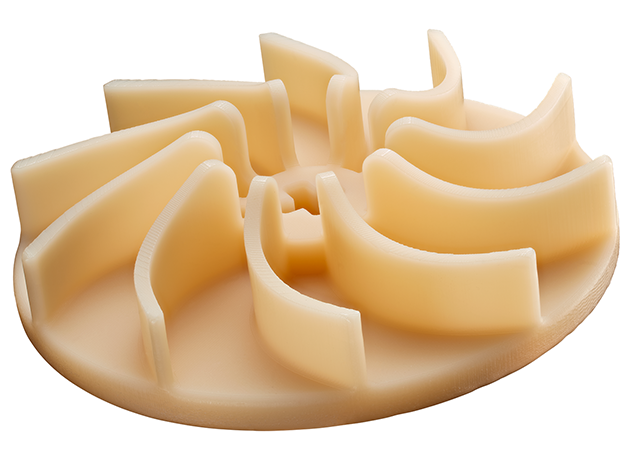

24/7 production of small, ultra-high resolution end-use parts

The P4K is the opposite of other, one-size-fits-all 3D printing solutions. With a range of models available, users can choose their optical configuration based on part size, feature-size requirements and throughput, and tailor a solution that best suits their needs. With resolutions of between 23µm-90µm on the X and Y axes, the P4K can easily produce detailed parts in a range of sizes.

Designed for a 24/7 production environment, the P4K can run lights-out, with little to no user intervention required. Easily print parts at volume with the quality, surface finish and tolerances needed for end-use applications

P4K Key features

Multiple high-resolution options

With resolutions of between 23µm-90µm on

the X and Y axes, the P4K can easily produce detailed parts in sizes ranging

from just 2mm – smaller than two grains of sand – to 230mm – about the size of

3 credit cards stacked end to end.

The P4K comes in four distinct models, each

utilizing a 4K projector. Distributing these pixels across four

differently-sized build plates allows for four different native pixel sizes (XY

resolution); 35,62,75, and 90 um.

MADE

POSSIBLE BY:

Four different model resolutions

Industrial DLP chips

Custom-designed optics

Designed for 24/7 production

The P4K allows you to take control of your manufacturing workflow with automated job queuing, managed by an onboard processor and hard drive, and automated job completion alerts to help minimize printer downtime. To further limit downtime, the build plate can be quickly swapped, allowing a new job to be started minutes after a print is completed.

MADE POSSIBLE BY:

Automated job queueing

Easy job turn over

Remote-managed enterprise software

Excellent reliability

Easy to use

User-friendly Envision One RP software automates all parts of the printing process, including support generation and part orientation, while a fully-integrated file repair tool patches mesh holes and readies parts for print. Easy, over-the-air updates for both software and firmware ensure users have access to the most up-to-date tools and print processes.

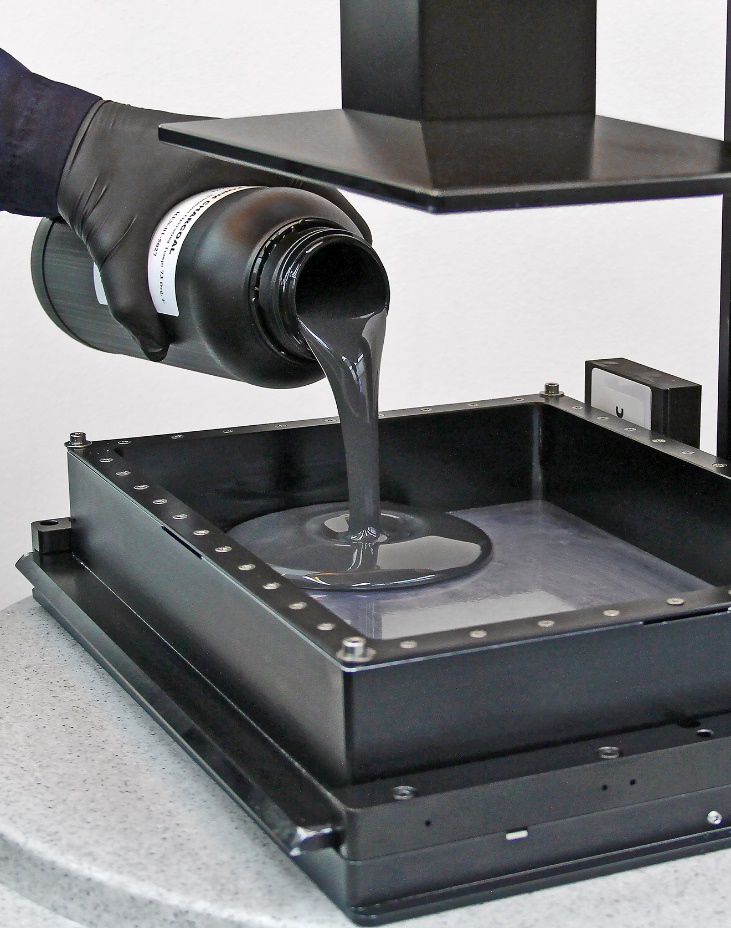

Easy material changes in less than two minutes allow users to produce a wide variety of parts with properties tailored to different applications, and excess material can be stored for months, helping users achieve further cost efficiencies.

MADE POSSIBLE BY:

Intuitive software

Under two-minute material changeover

Designed for serviceability

|

|

HARD PLASTIC

KEY FEATURES High flexural modulus Hydrophobic High impact resistance Great surface finish |

|

||||||||||||||||||||||||||||||||||||||||||

|

HIGH TEMP Molding material designed for high-temperature and high-pressure applications

KEY FEATURES Heat deflection of 140°C straight of out the machine High stiffness Able to be vulcanized in rubber |

|

CASTABLE Castable material with the highest wax content available in 3D printing

KEY FEATURES Highest wax content available for 3D printing Great for small and large features No ash content |

|