Envision One

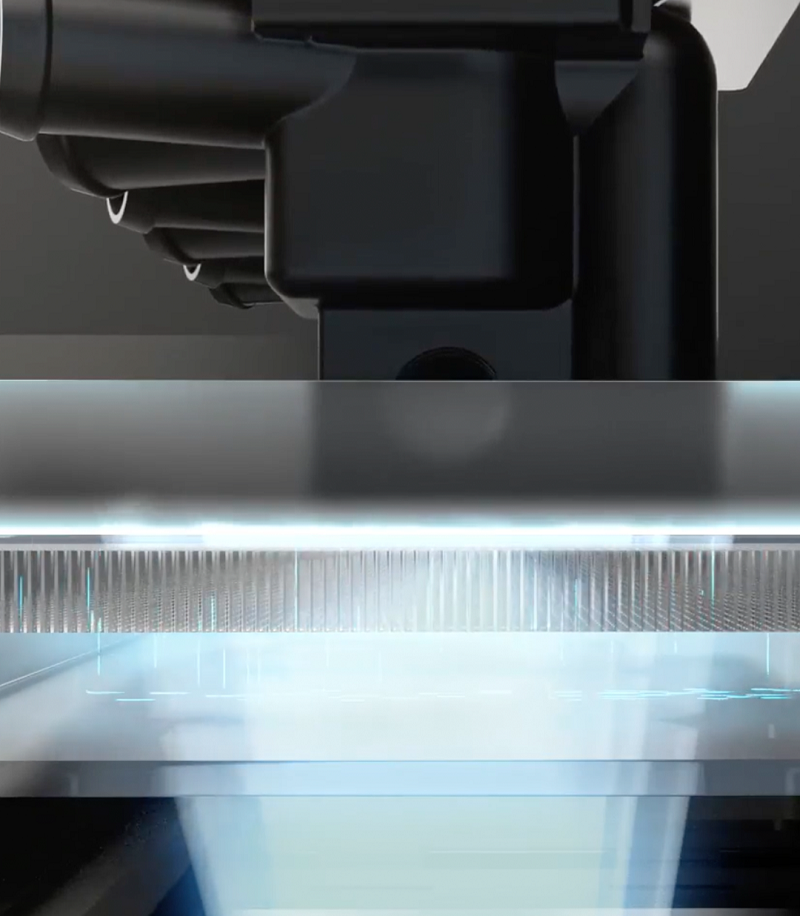

The Envision One features patented CDLM (continuous digital light manufacturing) technology, which enables the ability for continuous printing. With little to no delay between layers, the Envision One delivers exceptional speed, print resolution, surface finish, and part properties.

Key Features

Finish an entire 3L build volume in just 4.5 hours – 30% faster than competing systems and 10x faster than desktop SLA.

Best-in-class part performance

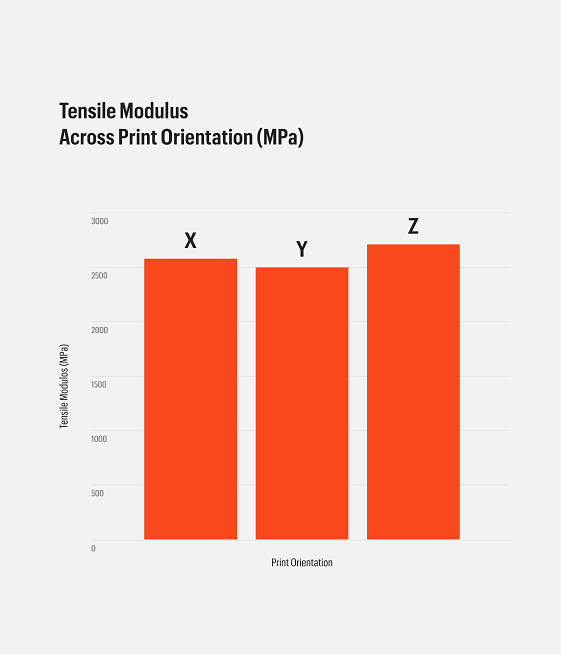

The Envision One leverages long-chain polymer chemistry to produce strong, stable parts. The result is isotropic parts suitable for end-use applications and capable of standing up to the most demanding conditions.

High accuracy and resolution

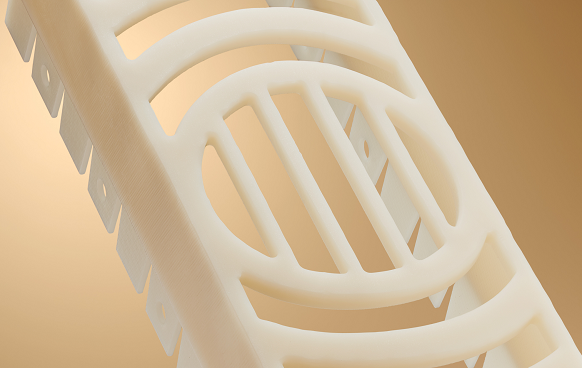

Featuring patented “domeless” printing technology, the Envision One eliminates any concerns about how “doming” may impact accuracy on the Z axis. High-resolution (60 um XY) printing and patented pixel tuning technology make it easy to create fine features and smooth surface finishes suitable for end-use parts.

|

High-speed continuous printing The cDLM process allows for continuous printing without the need to peel each layer off the film after it is polymerized. A ‘dead zone’ is formed by flowing a thin layer of oxygen above the film of the printing bed. Within this ‘dead zone’ the polymerization process is inhibited ensuring the layer being printed adheres to the layer above and not the printing bed film. This ‘dead zone’ is what enables continuous printing, where the build plate can continually move in the Z axis, leading to faster, more reliable prints.

|

High-resolution printing

|

|

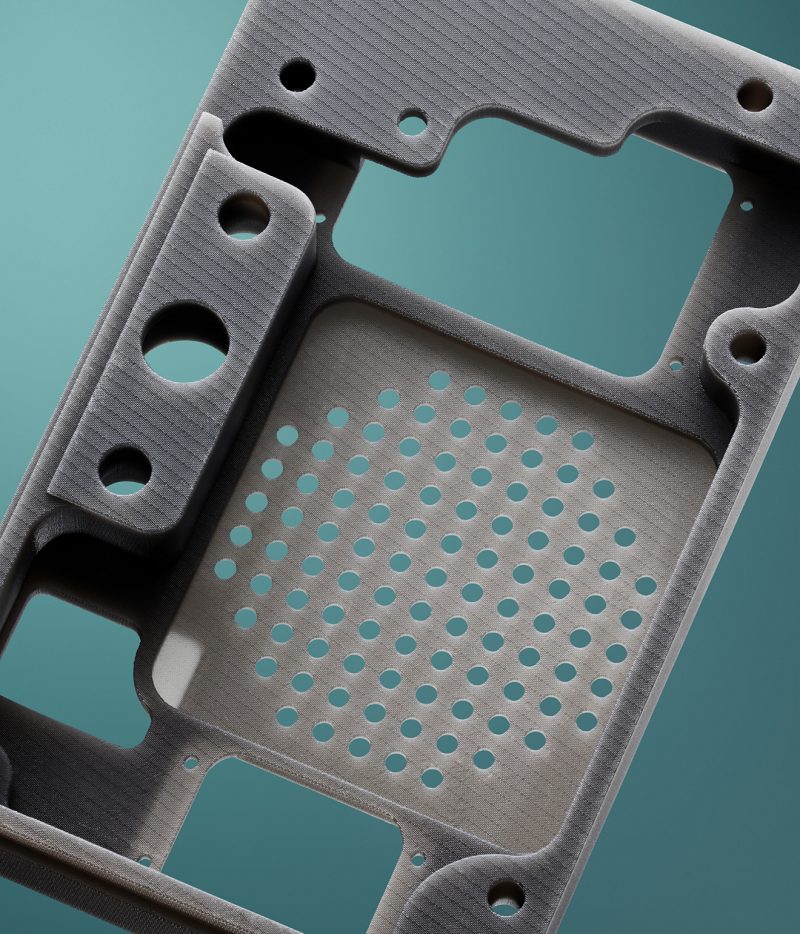

Best-in-class part performance The Envision One cDLM produces end-use parts with properties that meet or exceed that of traditionally manufactured plastic components, such as injection molded plastics

|

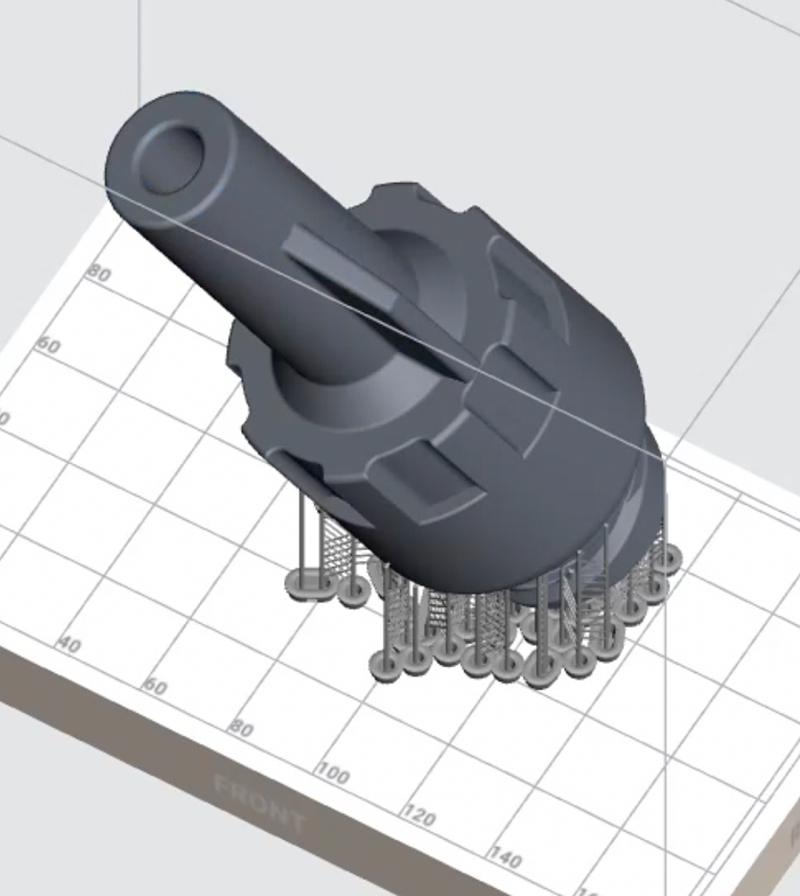

Easy to use software The brains of the Envision One cDLM is EnvisionONE RP which streamlines the entire fabrication process, ensuring optimal part orientations, print settings, and printer productivity.

|

Example Parts

|

|

|

|

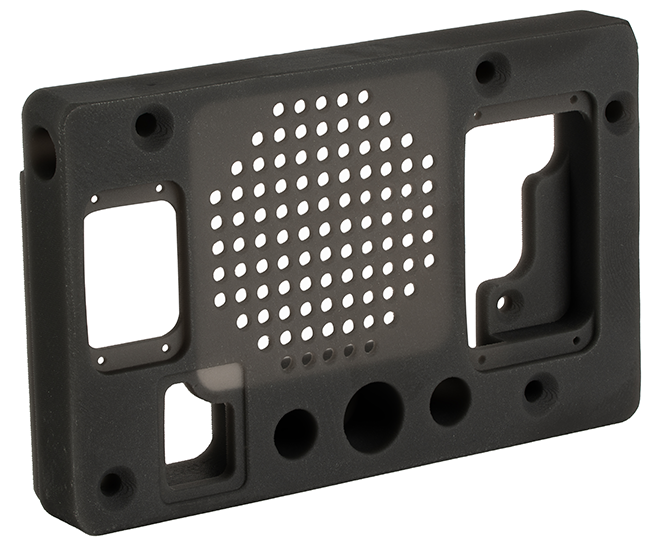

4 Barb Manifold This manifold is a heater control valve housing, which accepts a metal actuator as well as other moving components. |

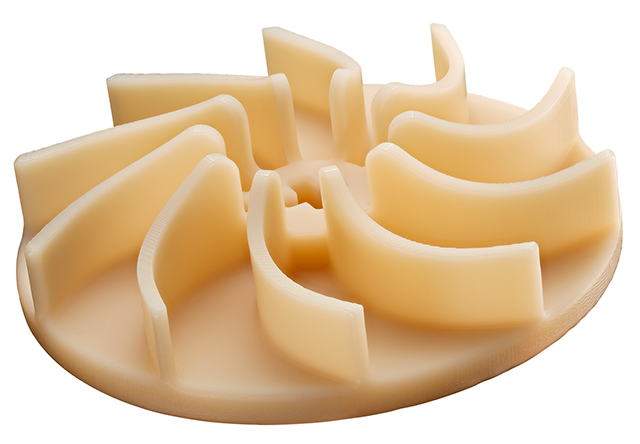

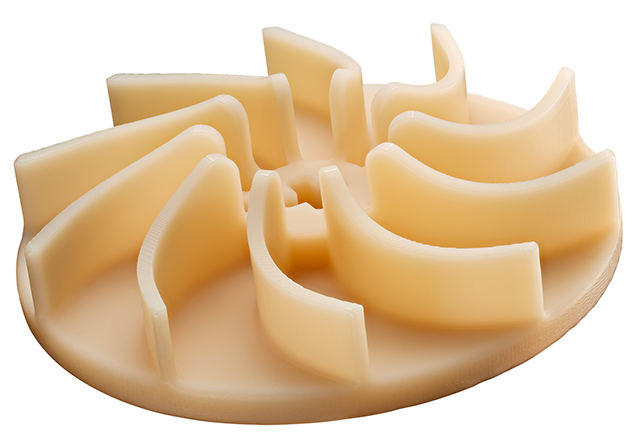

Pump Impeller Rotating pump component used to agitate fluid and stir components together. |

Spray Nozzle This nozzle sprays input fluid into a fine mist for better absorption. |

|

||

|

Fuel Line Clip

A fuel line clip designed with a snap fit used in the automotive industry |

Featured Materials

ETEC provides over 190+ material with various mechanical properties and features.

|

|

|

| Locitite 3955 HDT280 FST | Locitite IND406 | Locitite E-3843 |

|

||

| E - ToughFlex |

Specification

|

|

Envision One |

|

Print Technology |

Continuous Digital Light Manufacturing (CDLM) |

|

Build Envelope |

180 x 101 x 175 mm 180 x 101 x 330 mm (XL Version) |

| Layer height | 50-150µm |

| XY Resolution | 60µm with patented pixel tuning |

| Models | LT, HT, LT XL,HT XL |

|

Compatible materials |

Locitite 3955 HDT280 FST Locitite IND406 Locitite E-3843 E -ToughFlex

|