新聞資訊

Formlabs 宣佈推出 Form 4:極速打印,精準無比 | 現正接受預訂

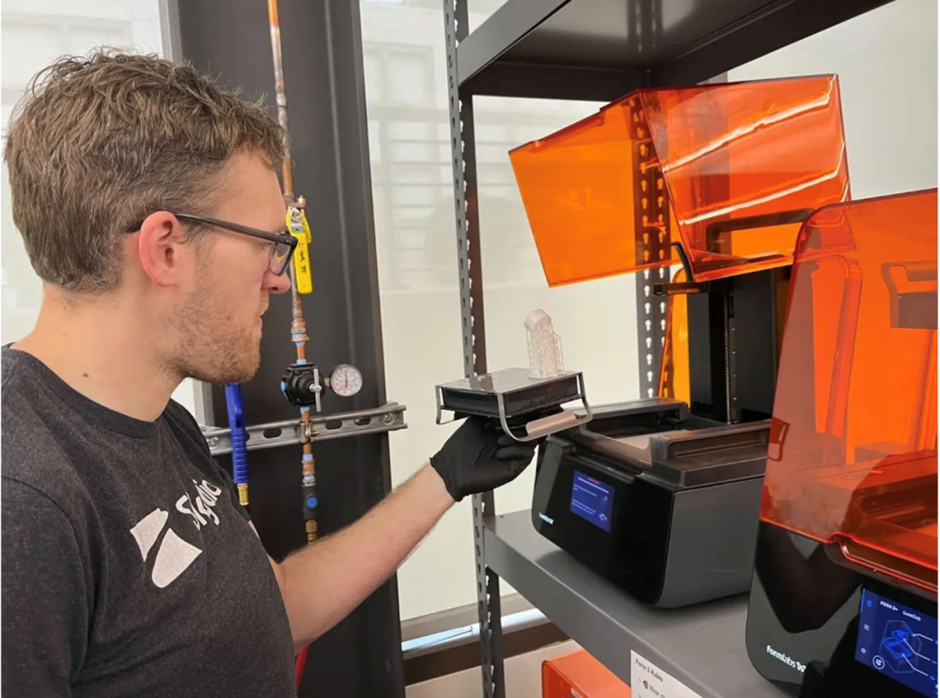

Formlabs 自豪地宣佈推出全新的 Form 4,這款新型樹脂打印機以驚人的速度、精準度和無可比擬的準確度打印。利用 Formlabs 生態系統的

MORE

04/18

2024

03/28

2024

03/20

2024

02/28

2024

02/28

2024

02/22

2024